Classification: PP+PET

Overview: Mainly used for engine fenders, roof panels, rear covers, trunk side panels, etc.

The increasingly demanding automotive interior parts materials need to modify and improve the performance of different polymer materials. We use advanced modification equipment and research on materials to develop products that can better meet the needs of our customers.

Sheets used in the production of automobiles:

*The left and right sides of the suitcase,

*Trunk lid cover,

*Splash pads (hub caps).

Our Technology

* Thermal lamination technology of lamination/cloth for interior parts (no glue, thermal lamination, environmentally friendly sheet)

*High and low temperature resistant and anti-aging PP sheet modification technology;

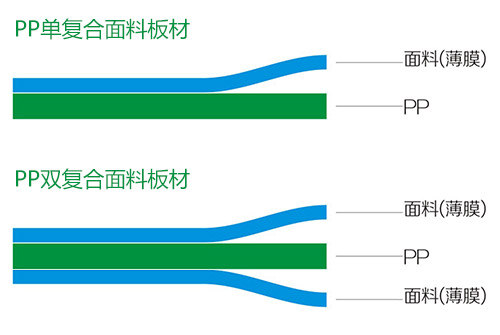

Production specifications: PP/PET single compound PET/PP/PET double compound, the width is larger than 1900mm, and the thickness is 1.0-6.0mm

Environmental performance - LWRT board is made of glass fiber and polypropylene, so it has excellent …

The PET sheet is extruded from polyester raw material at high temperature, and the thickness of the s…

GMT sheets are made of fiberglass mat and thermoplastic polypropylene resin. Due to its low material …

轻质GMT板材具有强度高、冲击韧性高、承载力好、耐高温、重量轻、可回收、不易变形、吸音隔音好、无异味等优…

EPDM rubber sheets are synthetic elastomers, which are officially known as ethylene propylene diene m…

Today, high-performance thermoplastics offer excellent impact resistance, durability, and heat resist…